Case Study

PPS Innovation Creates ATV Manufacturer Solution

PPS Engineers & Fabricators Develop Custom Solution for Unique Challenage

Problem

An ATV customer’s frame-stripping order initially posed significant handling challenges during the chemical tank-loading process. The PPS-Huntsville team relied on straps and clevises, which were constantly being damaged by pressure washers. These components deteriorated rapidly, leading to safety concerns, frequent replacements, and downtime.

Additionally, only one frame could be processed at a time due to setup limitations. This not only slowed down production but also left sections of the frame unprocessed where straps had been placed, affecting paint consistency. As production demands grew, it became clear that this process was inefficient, labor-intensive, and ultimately unsustainable for meeting output goals while maintaining high quality for the customer.

Solution

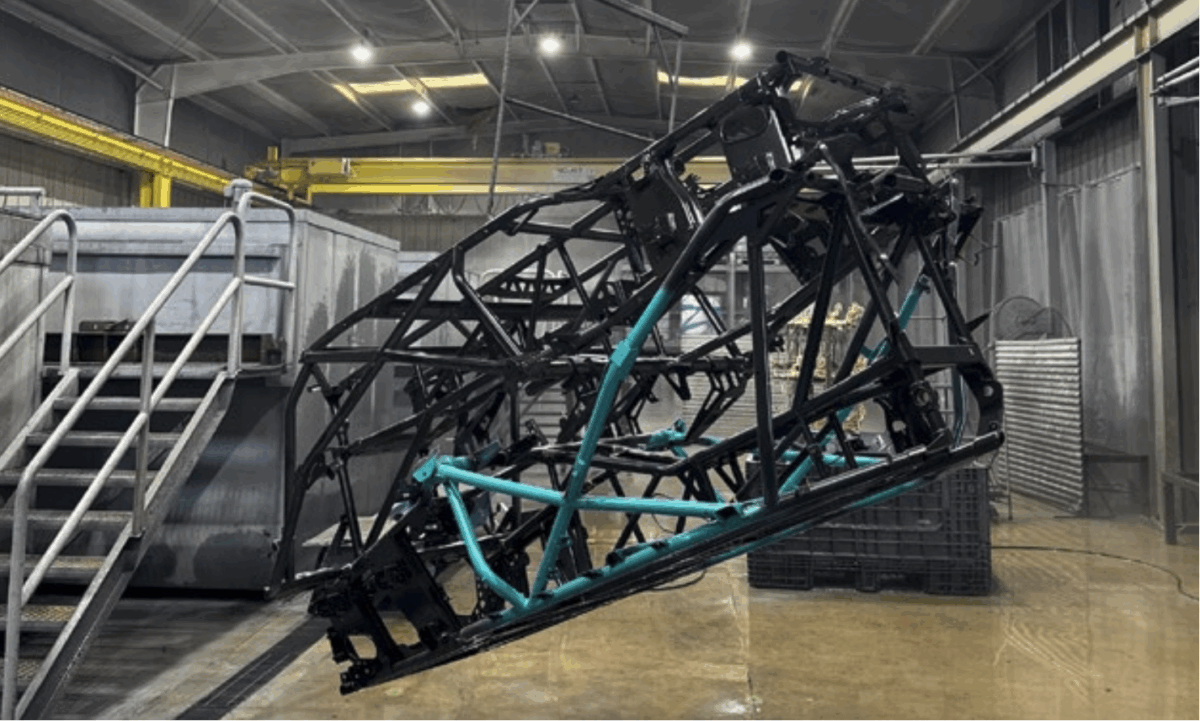

The PPS team engineered a custom support system using quarter-inch steel plates, approximately 1.5 feet long, and brackets that were 1 inch wide, 1 foot long, and a quarter-inch thick. These components were bolted to the frames at a 45-degree angle using existing pre-threaded bolt holes with nuts welded inside the frames, ensuring a secure and stable connection without compromising the frame’s structure or finish.

To accommodate the awkward shape of the ATV frames, the PPS team developed a technique where two identical frames are processed simultaneously - one placed in a standard upright position and the other flipped upside down. A forklift is used to support and align the frames during setup on a pallet, allowing for precise positioning and ease of assembly.

Once secured with the brackets and plates, the frames are lifted into the tank using a custom-designed metal crane attachment, which allows the frames to be lowered into the tank and then detached. When processing is complete, the attachment is reconnected to retrieve the frames, streamlining both entry and exit.

The PPS team also introduced a preliminary wash and inspection process after retrieval, separating the frames for a more thorough cleaning before final rust prevention (RP) treatment. Looking ahead, a future enhancement includes the use of magnetized guide bars that would protrude from the chemical solution.

This solution transformed a cumbersome and time-consuming process into a repeatable and safe system that significantly improved operational efficiency and reduced turnaround time for the customer.

Results

The new system immediately halved the processing time - cutting it from eight hours for two frames down to just four. Weekly production jumped from six frames to twelve, effectively doubling out- put with the same labor. This streamlined process significantly improved workflow, reduced physical strain on employees, and minimized material waste. The custom setup provided customer savings through enhanced paint coverage and reduction in rework through the elimination of previously problematic strap marks.

With minimal investment in materials and setup time, the new approach delivered a substantial return in preparation, profitability, and customer satisfaction. Overall, this innovation has turned a frustrating bottleneck into a scalable, efficient, and safer operation for ATV frame processing.