Case Study

Rapid Turnaround for Heat Exchanger Company

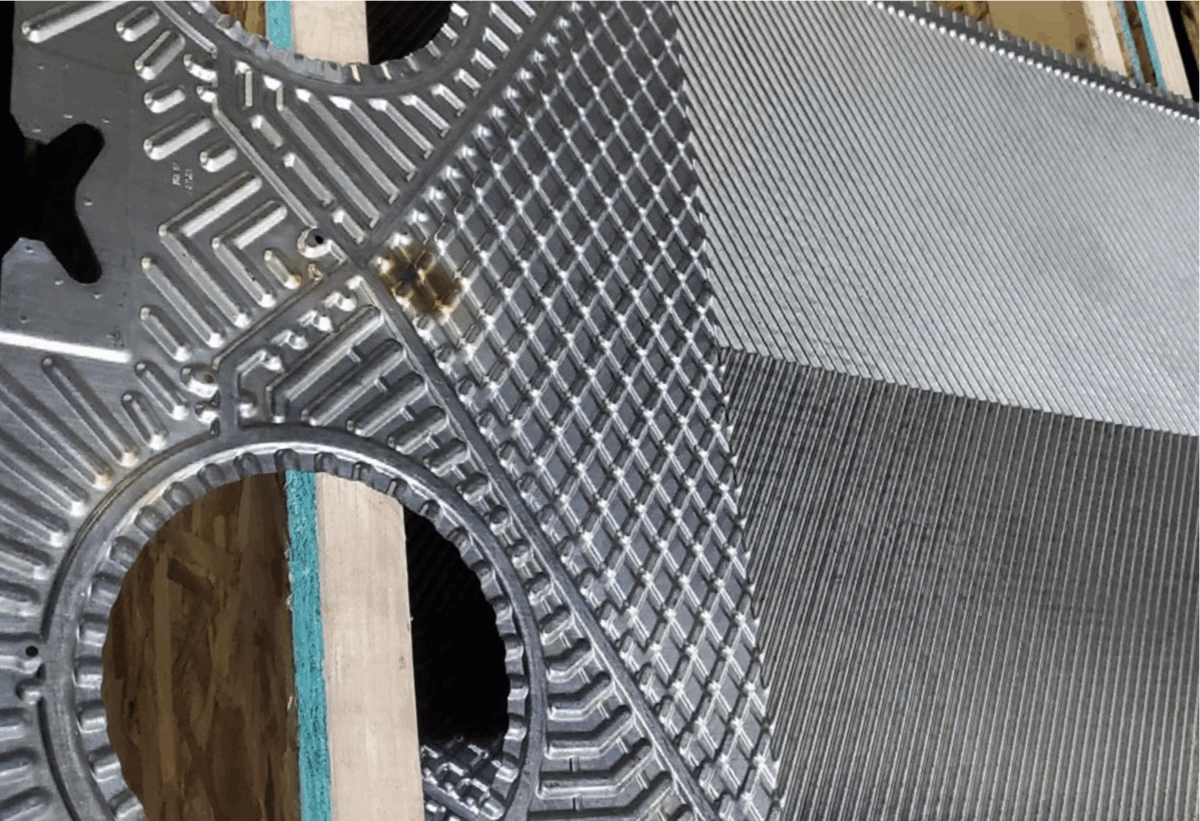

PPS's Rapid Restoration of 1,600 Heat Exchanger Plates with Flawless Precision

Problem

A heat exchanger company faced a critical operations dilemma. A significant backlog of heat exchanger plates required urgent cleaning to avoid disrupting the company’s production schedule, whose in-house chemical cleaning system had failed to meet performance expectations. Coatings were left partially intact, which extended turnaround times.

These issues compromised equipment performance and risked missing client deadlines. The heat exchanger company needed a fast, reliable alternative that wouldn’t sacrifice quality or safety. Time was of the essence, and only a trusted partner capable of precision, speed, and scale could meet the challenge.

Solution

The heat exchanger company initiated a test run with PPS, sending 200 plates to the Toronto facility to evaluate a chemical cleaning alternative after traditional thermal methods had failed to deliver satisfactory results. PPS implemented a targeted caustic strip method, specifically formulated to remove heavy coatings without compromising the structural integrity of the plates. This approach used controlled chemical concentrations, precise temperature management, and optimized dwell times to ensure consistent, thorough cleaning.

To validate the method’s effectiveness and ensure safety, PPS technicians monitored each phase of the process closely, tracking chemical performance and material condition. The results exceeded expectations: all 200 test plates were returned within 48 hours, fully cleaned, damage-free, and ready for immediate reassembly into the customer’s operations. The speed, quality, and reliability of the turnaround demonstrated PPS’ readiness to handle complex, high-volume work.

Impressed by the outcome, the heat exchanger company immediately authorized a full-scale rollout - 1,400 additional plates - with a one-week completion deadline. PPS rapidly mobilized internal resources and coordinated across its operations, engineering, and logistics teams to prepare for the scale-up. Modifications were made to racking systems and workflow layouts, ensuring safe, efficient handling of the larger batch without compromising turnaround time or quality.

Results

Drawing on insights from the initial trial, PPS reconfigured existing racking systems and adjusted workflow layouts to accommodate the larger load efficiently. Custom modifications allowed more plates to be processed simultaneously while maintaining quality assurance checkpoints at every stage. Staff worked in staggered shifts to sustain around-the-clock productivity. Communication between the project leads, operations team, and the customer remained continuous throughout the week.

As a result, all 1,400 plates were processed, quality-checked, and returned on schedule. The project reinforced PPS’ ability to deliver high-performance, high-volume solutions under pressure - earning the heat exchanger company’s confidence and opening the door to future collaborations on even larger projects.